- Home

- About Us

- Products

- Services

- News

- Contact

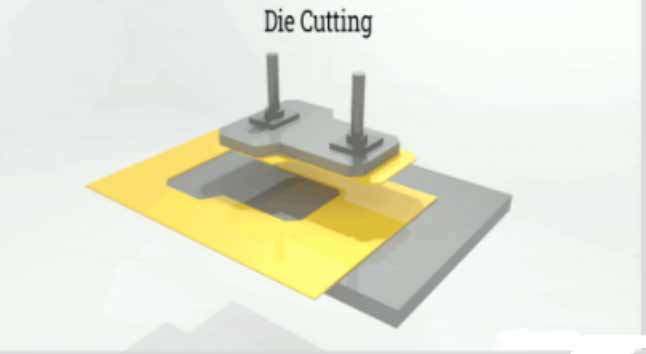

What is Die Cutting?

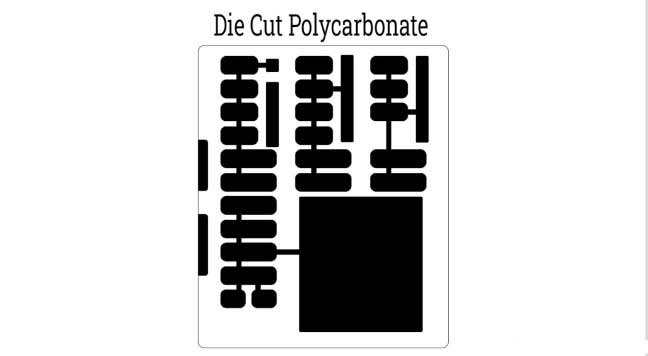

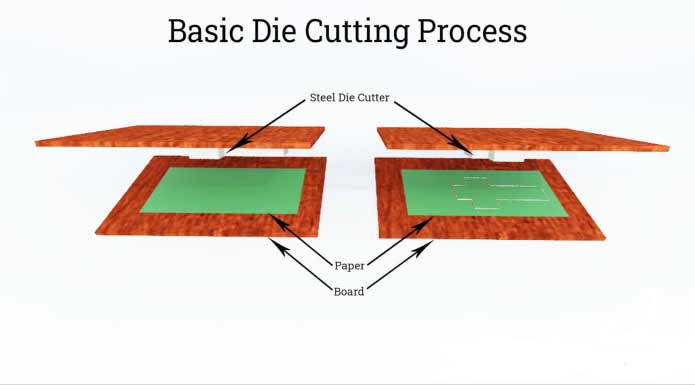

Die cutting is a mass fabrication process for cutting out shapes by shearing stock materials such as paper and chipboard using a die, which is a specially crafted tool used for cutting or shaping a material. The die has sharp edges to pierce the material; and has the two-dimensional shape of the finished part. The die cutting process works on the same principle as a cookie cutter where the dough is cut into smaller sizes. Materials that can be die cut include paper, fabrics, rubber, fiberglass, metal sheets, foam, wood, and plastics.

Die cutting was introduced during the first industrial revolution as a method for modernizing the shoemaking industry. Before it was invented, fabricates were outlined and cut the soles of the shoes by hands, a process that required more time and manpower and had a very low production rate. Die cutting resolved those problems. Patterns were made allowing shoemakers to replicate and standardize the sizes of the soles. Through years of discovery, die cutting revolutionized other industries and is still evolving to cater to increasing demand and in making more complex designs.

The process of die cutting has easily adapted to the technological age. Modern die cutting is an automatic or semi-automatic process using computer aided designs (CAD) that are programmed into a CNC machine. It is a method that is widely used in the manufacturing of packaging, consumer goods, and automotive parts. The use of die cutting can be found in DIY projects and offices.

Die cutting is a more efficient and faster method for producing parts and components, depending on the speed of the stroke, the method for feeding, and the type of die cutting machine. It has been found to be a faster method than waterjet and certain forms of blade cutting. The initial costs of die cutting are easily recouped by its efficiency, speed, and excellent quality.

Since it is a simple and straightforward process, die cutting is suitable for low or high volume manufacturing. In industrial applications, the machine may be located directly downstream, while the starting material may be the outgoing product from a preceding process. The die cutting machine also has many capabilities, making it a versatile and useful asset. It can perform other operations aside from cutting, such as forming, perforating, and scoring. The process is done on a press through a single or series of strokes.

Flatbed, rotary, and semi-rotary die cutters are considered industrial-scale die cutting machines, designed for thicker and more rigid substrates able to produce parts at a fast turn around. Meanwhile, manual and digital die cutting equipment are utilized to create simple and accessory parts. Its production rate is relatively slower and therefore suitable for low volume orders.

-

4th Floor,No.428 Wenzhou Avenue,Puzhou Street,Longwan,Wenzhou,China,

-

+86-577-66688057

+86-18058846873 -

Copyright © 2019 CHINA . Wenzhou Andy Printing Machine Factory and Suppliers.